We’re a leader for quality condition monitoring

BUILDING FOR THE FUTURE

We pioneer the condition monitoring solutions that change the way you work

Brüel & Kjær Vibro has set new standards in vibration measurement and monitoring of rotating machinery. Our product lines comprise permanently installed online condition monitoring systems as well as portable off-line solutions.

- Detect and fix faults faster

- Make smart, data-driven decisions

- Continuously improve your process

What would you like to know?

Key features of BKV Beyond®

Prevent faults, keep your machines running longer, and power up your process. BKV Beyond® delivers reliable benefits that give your machine performance the freedom to thrive.

Always Learning

BKV Beyond® doesn’t stop – our AI keeps adding to its understanding of how you work, helping to identify developing problems even faster, and identifying insights that will power up your processes.

Saving you time

You can’t afford to stop production for a false alarm. Our qualified engineers approve every BKV Beyond® notification, so your maintenance team acts only when needed, keeping your machines running for longer.

Reducing your costs

BKV Beyond® lets you push the limits of your process, preventing costly unplanned downtime and product defects. Data-driven insights will help extend the life of your equipment and reduce maintenance costs.

Reliable solutions

at all levels

- For Maintenance Managers and Engineers

- For Executives and Senior Managers

- For IT and Technology Leads

Industries we work in

Our machine condition monitoring solutions for rotating machinery are in use in industries around the world.

Getting started with BKV Beyond®

It’s easy to get your BKV Beyond® solution up and running, with components that integrate seamlessly, and intelligent condition monitoring software tools to help you work smarter. Start with our free Value Vision consultation service, which helps you build a roadmap from stakeholder alignment to project governance, ensuring the best outcome and ROI.

Collect data

Monitor your machines with our advanced sensors, including the completely wireless BKV Collect® sensor, which fits directly to your machine for speedy installation.

Set-up support

Our software tools help you fit your sensors even faster. The BKV Deploy mobile app helps you to install your BKV Collect® sensors, while BKV Ignite lets you map your plant assets for monitoring.

Connect your system

BKV Connect® gateways bring together all your sensor data securely, and centralize your communications.

Correct faults

Artificial intelligence analyzes data from across your business. This is then verified by our experts, allowing you to work smarter with actionable insights.

MAKE THE CONNECTION

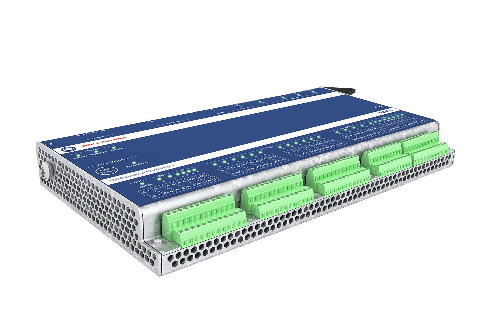

VCM-3 Condition Monitoring Unit

Boost the productivity of your production processes with the VCM-3 – a flexible edge device that offers a revolutionary monitoring approach for highly dynamic assets. Designed to connect even complex machinery, the VCM-3 merges asset health and process-related signals to help you make informed decisions.

Frequently asked questions

Condition monitoring allows the prediction of equipment health and performance by recording and analysing sensor data for key measurement parameters. Condition Monitoring as a Service (CMaaS) is, typically, a subscription-based offering that allows operators to benefit from predictive maintenance without the need to build in-house expertise for vibration analysis. It is based on specialized sensors, data analytics tools, and cloud-based platforms to monitor the health and performance of the equipment remotely. By adopting Condition Monitoring as a Service, organizations can benefit from improved asset reliability, reduced maintenance costs, increased equipment lifespan, and enhanced overall operational efficiency, enabled by expert advice and actionable insights provided by trusted partners.

Condition monitoring software plays a key role in helping businesses to maintain the health and reliability of their assets while optimizing maintenance practices and reducing operational costs. It enables the early prediction of equipment failures, helps prevent downtime, allows the optimization of maintenance schedules, and ultimately helps to improve operational efficiency. It also delivers peace of mind to machine operators, who can be confident that their monitored machines are not likely to break down unexpectedly, and allows for more data-driven decision-making when maintaining or improving assets.

Begin your journey with BKV Beyond®

Ready to unleash performance and power-up your plant? Take the first step on your journey towards continuous improvement today.

Get Started